Engineer Your Thermal Management Solutions for Optimal Performance

Welcome to SJS Products, a Jamcor Corporation, your trusted partner in advanced Thermal Management Solutions. With extensive experience in the field, we specialize in the design and manufacture of heat sinks, vapor chambers, and heat pipes. Explore our Thermal Solutions and discover how we can elevate the performance of your engineering projects.

Comprehensive Thermal Solutions

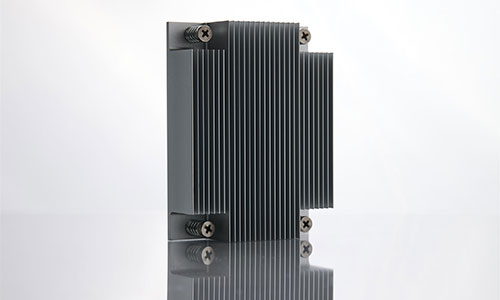

At SJS Products, we offer a comprehensive range of Thermal Solutions designed to meet the unique requirements of various industries. Our expertise covers the design and manufacturing of heat sinks, heat pipes, oscillating heat pipes, and vapor chambers. Heat pipes efficiently transfer heat from the heat source (evaporator) to a cooler location (condenser), ensuring rapid and efficient heat removal. An oscillating heat pipe is a heat transfer device that utilizes capillary action and oscillatory motion of a working fluid to efficiently transfer heat from a heat source to a heat sink, enabling efficient thermal management in various applications. Vapor chambers excel at dissipating heat in three dimensions (x, y, and z-axis), making them an excellent choice for high-wattage systems. Given the heat generation in engineering processes and numerous household and industrial appliances, precise thermal control is essential.

Harnessing the Power of Evaporation and Condensation

Heat pipes and vapor chambers leverage the principles of evaporation and condensation to facilitate efficient heat transfer. This process, rooted in physics, effectively converts heat energy into gas, enabling effective cooling. You can witness a similar cooling cycle in your household fridge and freezer, where compressors and other components process and convert heat. This technology finds applications in air conditioning systems and various other fields. At SJS Products, a Jamcor Corporation, we leverage our expertise in Thermal Solutions to deliver unparalleled performance. Contact us today to discuss your specific needs and find answers to your questions.

Industries Leveraging Thermal Solutions

Heat sinks, heat pipes, and vapor chambers play a crucial role in the electronics and automotive industries. Manufacturers of household appliances, including refrigerators, freezers, and air conditioning systems, also rely on these components. While the concept may seem straightforward, the design and manufacture of these thermal solutions demand expertise in the field. At SJS Products, a Jamcor Corporation, we take pride in delivering optimized solutions crafted by our team of skilled engineers.

Comprehensive Analysis and Expert Guidance

When your next engineering project calls for heat sinks, SJS Products is here to support you. We provide comprehensive analysis and expert guidance to ensure the optimal selection and implementation of thermal management components. Our knowledgeable team is committed to assisting you and setting your project in motion. Contact us now to explore how our expertise can contribute to your success.

Unmatched Service and Support

At SJS Products, a Jamcor Corporation, we take great pride in providing exceptional services to our clients. As your partner in thermal solutions or any other manufacturing and engineering support project, we go beyond the offerings of ordinary suppliers. Our experience in engineering support and Thermal Solutions has resulted in successful partnerships on numerous engineering projects. Whether you seek information on heat sinks, heat pipes, and vapor chambers or require expert guidance on general engineering support and manufacturing solutions, our team is ready to assist you. Let us be the partner that drives the success of your next project. Contact the team today.

Read further about the two main manufacturing processes used in the creation of heat sinks and heat exchangers: Extrusion, and CNC Machining.